November 15, 2022

Why Quality Management Systems are critical for Medical Device companies

The most effective and successful companies in highly competitive industries have placed a large emphasis on quality. Quality is defined differently in each industry. Quality is a critical product attribute and arguably, an essential attribute for medical devices. Demonstrating capability to manufacture a high-quality medical device is dependent on many elements: documentation control, design control, resource management, production and process control, material control, management responsibility; to name a few. To consistently maintain and deliver high quality medical devices, and continuously improve this quality level, requires employee commitment at all levels in the organization. It needs to be part of the organization’s culture. It should simply be part of the day-to-day operations for all disciplines and not limited to the quality and manufacturing departments.

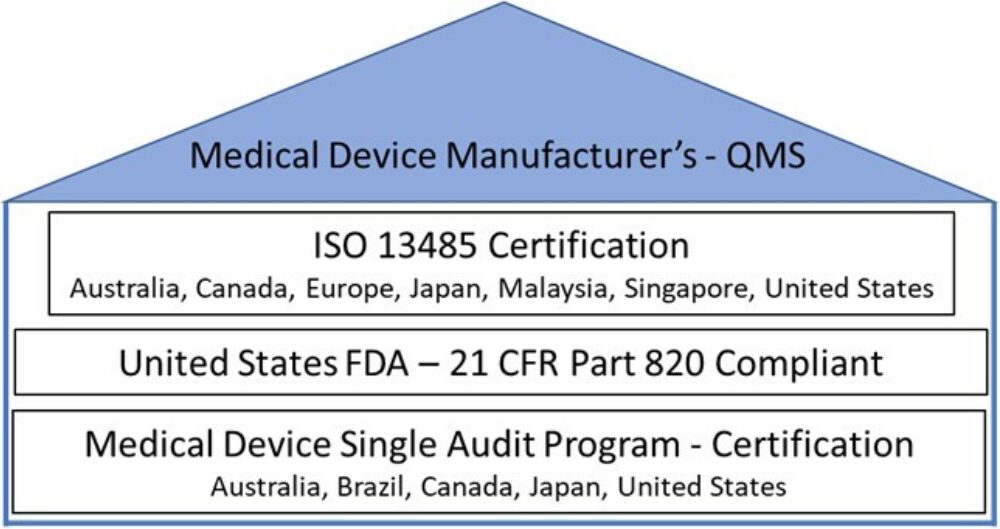

A quality management system (QMS) is a requirement to manufacture and sell certain medical devices in most countries. The highly recognized global industry standard which contains a quality management system for the design and manufacture of medical devices is published by the International Organization for Standardization (ISO), ISO 13485. The current edition was published in 2016: ISO 13485:2016.

The quality systems for products manufactured and / or sold into the United States are referred to as current good manufacturing practices (CGMP’s). The CGMP requirements are detailed in the Code of Federal Regulations for devices, 21 CFR Part 820. The CGMP requirements are flexible to a specific medical device. CGMP’s entails documented specifications and established controls which assures and provides evidence that the finished medical device consistently meets the specification, which helps assure their safety and efficacy. The United States Food and Drug Administration (FDA) has published a proposal to harmonize its QMS (21 CFR Part 820) to ISO 13485 (Quality System (QS) Regulation/Medical Device Good Manufacturing Practices | FDA). It is recognized by FDA that there are considerable similarities between 21 CFR Part 820 and ISO 13485 to seriously consider the merging of these requirements, with the potential for some additional amendments depending on the type of medical device. FDA accepted comments on this proposal from stakeholders until May 2022 and the final ruling is pending.

Medical Device Single Audit Program (MDSAP) is a single regulatory audit of a medical device manufacturer’s quality management system. It aligns with the requirements of ISO 13485 plus additional quality management requirements to meet the regulatory requirements from Australia, Brazil, Canada, Japan, and the United States. MDSAP audits are conducted by MDSAP recognized Auditing Organizations. Typically, the medical device manufacturer will have an initial certification audit followed by annual surveillance audits. Achieving MDSAP certification enables a medical device manufacturer to sell their devices in Australia, Brazil, Canada, Japan, and the United States and it provides evidence of a comprehensive quality management system, including certification to the globally recognized ISO 13485 standard. Achieving MDSAP certification provides customers with additional assurance they are receiving safe and reliable products.

Cryostasis’ Quality Management System for our proprietary storage solutions and temperature and pressure control systems is a critical success factor. The company is being scaled on the foundation of our QMS. More to come in future blogs.

We’re on a mission to enable lifesaving research and improve patient outcomes around the world.

Join Us